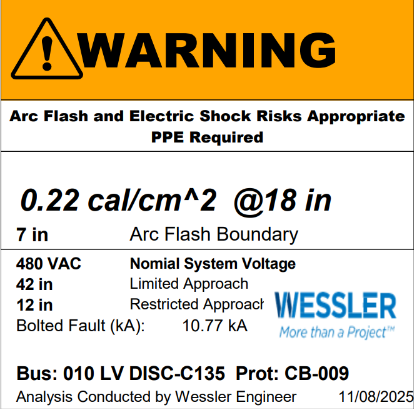

When most people think of arc flash safety, they picture the hazard labels on electrical panels that are bright, bold warnings with calorie ratings and PPE requirements. And while those labels are crucial, they’re only the beginning. A truly effective electrical safety strategy goes far beyond compliance stickers. It requires a comprehensive Electrical Safety Program rooted in NFPA 70E, one that keeps your people safe, your documentation clear, and your operations resilient.

In this post, we take a look at what building a full-cycle safety program really involves, and how utilities, municipalities, and facility owners can move from “check-the-box” to “culture-of-safety.”

What Goes Into an Electrical Safety Program?

According to NFPA 70E, a complete program doesn’t just identify hazards, it manages them continuously. A robust Electrical Safety Program should include:

-

-

Formal policies and written procedures

-

Documented risk assessments and engineering analysis

-

Up-to-date single-line diagrams

-

Arc flash labeling based on actual system conditions

-

Safe work practices, including lockout/tagout and limited approach boundaries

-

Routine audits and program reviews

-

Roles & Responsibilities: Qualified vs. Unqualified

A critical distinction in any Electrical Safety Program is the definition of “qualified” personnel. NFPA 70E outlines the training, experience, and demonstrated skills required for someone to be considered qualified to work on or near energized equipment.

-

-

Qualified workers must be trained to recognize hazards and know how to avoid them. They must also understand how to use PPE and safety equipment appropriately, and be familiar with the specific electrical systems they work on.

-

Unqualified workers, on the other hand, should be restricted from access to exposed energized conductors and must be protected via boundaries, signage, and supervision.

-

PPE Selection and the Importance of a PPE Matrix

Personal Protective Equipment (PPE) is a key layer of protection, but it’s not one-size-fits-all. Developing a PPE matrix tailored to your facility helps match the hazard levels of each task with the appropriate gear.

A typical PPE matrix might include:

-

-

Create PPE selection based on set incident energy ranges to minimize equipment needed and simplify PPE selection process

-

Clothing and arc-rated suit requirements

-

Face shields, gloves, balaclavas, and boots

-

Tools and insulated equipment

-

Energized Work Permits: A Culture Shift

One of the most overlooked, yet powerful, safety tools is the Energized Work Permit.

If electrical equipment can be de-energized before servicing, it must be. When energized work is justified (for example, due to testing requirements or operational constraints), a permit:

-

-

Documents why energized work is necessary

-

Confirms risk assessments and boundaries

-

Identifies the PPE and safety precautions

-

Requires supervisory authorization and sign-off

-

Training Frequency and Documentation

Training isn’t a one-and-done event, it’s a continuous investment. NFPA 70E requires refresher training at least every 3 years, and anytime:

-

-

Equipment or job duties change

-

An incident or near-miss occurs

-

Safety audit findings identify a gap

-

Final Thoughts: Safety is Systemic

Hazard labels may catch the eye, but they don’t build a safety culture. A true electrical safety program is:

-

-

Proactive, not reactive

-

Empowering, not restrictive

-

Team-based, not just technician-based

-

Tags