CIPP is a method that can be used to rehabilitate existing pipes such as sanitary sewers, storm drains, and pressure pipes.

The method can be used to line circular pipe and a variety of noncircular pipe such as egg shapes, ovoids, and box culverts. In this post we cover how CIPP works, liner materials, installation methods, and cost benefits.

HOW IT WORKS

Prepping the Pipes

The pipe being lined via CIPP must be removed from service during the time of installation and during the service lateral the reinstatement process. Bypass pumping of sewer flows may be necessary.

Before lining, the pipe is cleaned and inspected via closed-circuit television. This flushes out deposits, debris and waste. Any protruding lateral connections are removed and local repairs are made to deformed or damaged exisitng pipe.

Materials and Design

CIPP liners of non-woven polyester felt or fiber reinforced fabric are manufactured to fit the host pipe. Liners are impregnated with a polymer resin, which when cured will form a close fitting liner pipe within the host pipe.

The liner can have sufficient thickness when cured to sustain the loads imposed by external groundwater, internal service pressure, and soil and traffic acting on the pipe.

The liner is thoroughly saturated with polyester, vinyl ester epoxy or silicate resin using vacuum, gravity or other applied pressure. The resin includes a chemical catalyst or hardener to facilitate curing. The outermost layer of the liner tube is coated with a polymer film to protect the liner during handling and installation. The impregnated liner may be chilled as it is transported to the job site to maintain stability of the resin until installed.

Installation

Inversion Method: CIPP liners may be installed using the inversion method, as pictured below at a recent Wessler project. The inversion method employs a scaffold tower to apply water pressure to turn the liner inside out and push it along the host pipe.

Another method is by winching liners into place through a manhole or special access point and inflating them to come into close contact with the circumference of the existing pipe. The liner is restrained in any intermediate manhole.

Another method is by winching liners into place through a manhole or special access point and inflating them to come into close contact with the circumference of the existing pipe. The liner is restrained in any intermediate manhole.

CIPP liners may be inflated or inverted with air or water pressure. Lengths may vary from short sections over a joint or defect, to full length linings of 300 to 600 feet. Lengths of 1000 feet have been installed in a single shot.

Curing and Testing

Temperature is important for curing. The liner can cure at ambient temperature, but there are ways to speed up curing through heat.

This is typically achieved through circulation of inversion water through a boiler, blending steam with inflation air, or by pulling through a UV light train.

Once the pipe cures, the liner must cool. The ends of the liner are then removed, flush with the pipe ends, and sealed where necessary. The curing water or steam condensate is allowed to escape and the trimmings cut from the liner are removed for safe disposal.

Finally, a sample of the liner is tested to make sure it meets performance specifications. A sample of the CIPP may be taken from pipe ends or from a mold cured under the conditions of manufacture.

When the lining is complete, the service connections are reinstated and the pipe is returned to service, typically on the same day.

BENEFITS

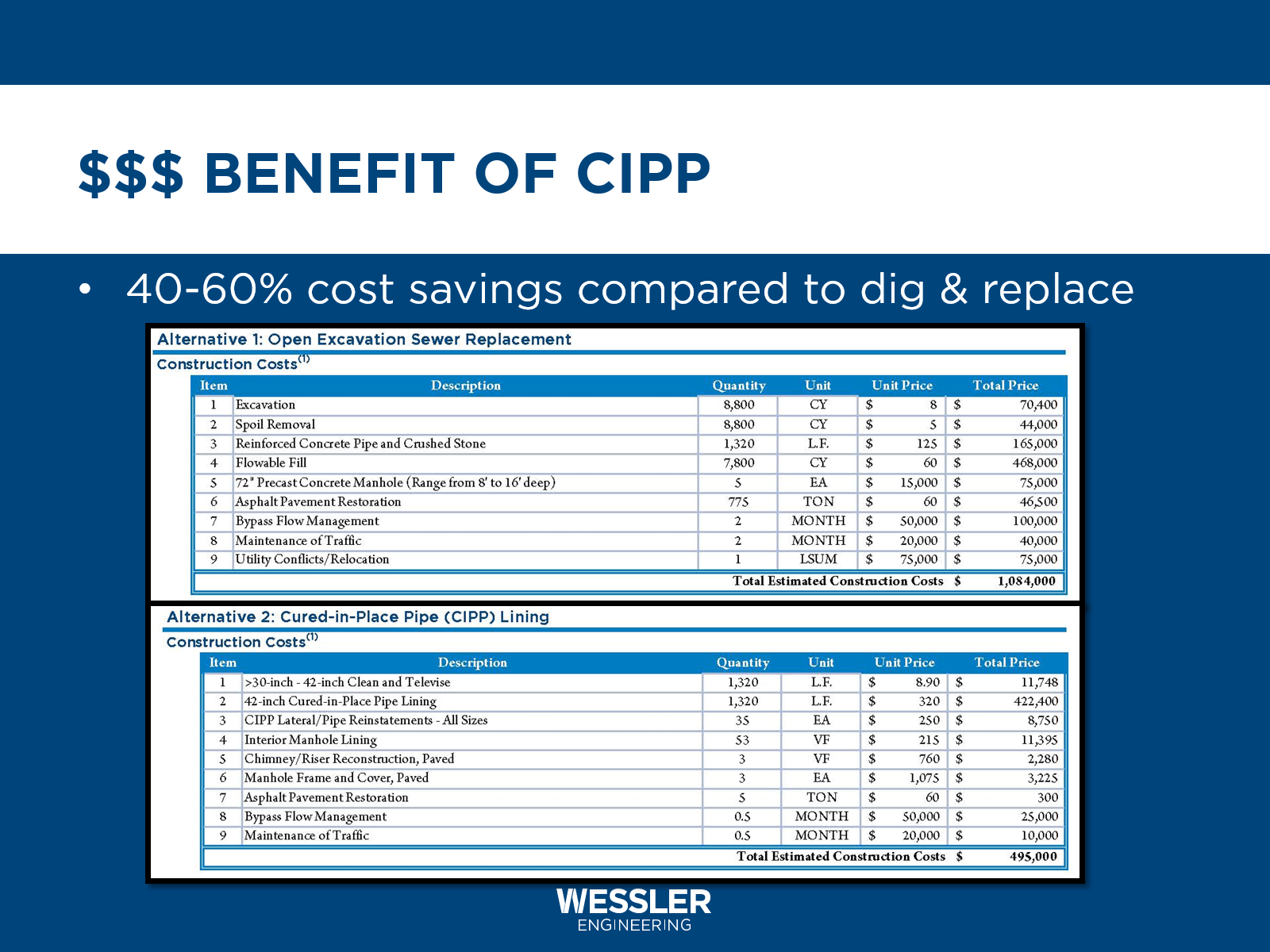

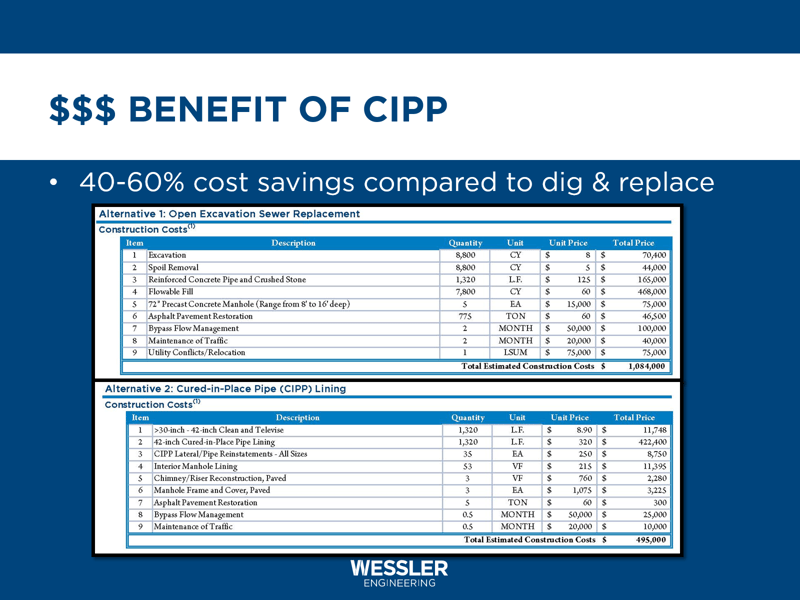

Compared to the costs of traditional dig and replace methods, CIPP can realize a 40-60% cost savings. Additionally, there are often fewer disturbances to traffic, customers and the environment when compared to dig and replace methods.

If you're curious to know more, ask me about the 80-inch CIPP liner installation project that Wessler worked on in December 2014. The International Society for Trenchless Technology is a good resource for information as well http://www.istt.com/guidelines/cipp-lining.

Contact us today if you have questions about CIPP.

Tags